CNC: machining 2mm acrylic

2013-04-11 12:37

| Categories: CNC

Starting new section in my blog about CNC machining. There will be notes about machining different parts from various materials. Today I will describe what speeds and feeds I am using to cut 2mm Acrylic (Plexiglas).

Starting new section in my blog about CNC machining. There will be notes about machining different parts from various materials. Today I will describe what speeds and feeds I am using to cut 2mm Acrylic (Plexiglas).

CNC router (introduction)

Just to remind you – I am using cheap CNC router from ebay. Here is my setup.

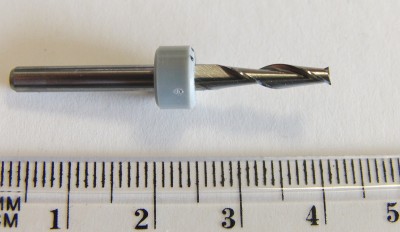

Cutter

- End mill: Carbide 3mm, 2 fl, Kyocera

|

diameter |

size |

# flutes |

length of cut |

shank |

OAL |

end-style |

|

.1181″ |

1/8″ |

2 |

.500″ |

.125” |

1.5” |

center-cut |

Machining parameters

- Feed: 350 mm/min

- Speed: 24000 RPM

- Cut depth 2mm (2.2 to make sure it cuts through)

Notes

- It’s recommended to blow (cool down) cutter with air. Else acrylic heats and instead of cutting it starts melting.

- Going to slow (feed) – acrylic starts to melt.

- Going to fast (feed) – cutter starts vibrating (basically because of router is not rigid enough)

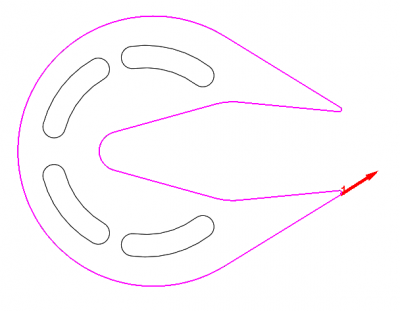

- Climb milling results cleaner surface.

This post is written in a very good and entails a lot of useful information for me. I am glad to find a good way of writing the post.When you want to build your own CNC machine there are literally thousands of plans and step-by-step websites that offer information on how to do it. The only thing you will have to decide is what type of CNC machine you want to make.

Kokią programinę įrangą naudojat ir kas yra “pigus CNC iš e-bay”?

Laimonai, pigus CNC – Sable 2015. O programinė įranga Mach3.