Precision steel touch probe for CNC machines

Starting new project – LP0018D – best in the class digitizing touch probe/edge finder. After long research and many adjustments finally preparation is complete. Time to review first samples. Like all of my previous projects it is funded completely from my pocket, so should be reasonably priced and I am not rushed by crowdfunding bull*hit.

Starting new project – LP0018D – best in the class digitizing touch probe/edge finder. After long research and many adjustments finally preparation is complete. Time to review first samples. Like all of my previous projects it is funded completely from my pocket, so should be reasonably priced and I am not rushed by crowdfunding bull*hit.

Introduction

This touch probes is made of tempered steel and electroplated, reference surfaces are grinded after. If this is not enough, it is completely hermetic, and filled with special dielectric fluid (which also enhances contact, stops oxidation, …). And if this is still not enough – all contacts (pins, balls, springs, and PCB will be coated in gold at least). So if you don’t crash it – it will be immortal.

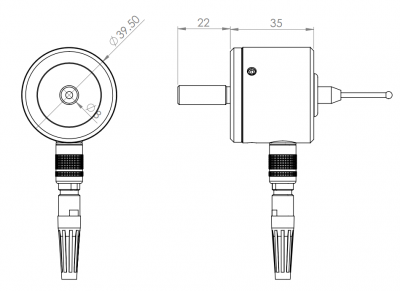

For testing I have made metric 8mm shank. I it will be good enough for most of machinists, but in future if there will be demand I will introduce other accessories.

At first let’s take a look at parts involved in this design. Did I mentioned – all parts are custom made from my carefully selected vendors/manufacturers. To be precise 7 of them.

- Steel base – hardened and black electroplated and grinded for precise reference surfaces

- Silicone gaskets

- Main compression spring

- Gold plated contact springs

- Gold plated dowel pins

- Gold plated steel balls

- Plastic parts to contain parts

- PCB (not yet from professional PCB house, but it will be ok for testing)

- Quick release snap action aviation grade (rated by manufacturer) connector

- Stylus with 3mm Ruby tip and M3 thread. (Renishaw compatible)

Can be purchased on Kurokesu e-shop

Today I just assembled one of these touch probes. Will test later and publish results. Initial tests seems positive. Stay tuned.

Adjustment

3 dowel pins glued unevenly (hey, first try to assembly), so trinocular part is slightly unbalanced. Good chance to calibrate, which is done via 3 set screws in the upper steel part. Here are some results.

Also, did I mentioned I am in love with this aviation grade connector. It makes a pleasant snap when connected.

Hello,

It would send one probe to the Czech Republic?

Thank you for answer.

Mirek

Hi Mirek. Sure, no problem. Please check your email for more details.

—

BR,

Saulius

I bought one of the pre-production units from EBay and I’m very pleased with it.

I did have a USA made probe but it was poor (impossible to centre and the repeatability was never better then 0.06mm no matter how much I played with speed and debounce). Fortunately(!), I crashed that into my vice and bought one of these probes to replace it.

I managed to get the new probe on centre to .002mm (the best I can measure with my DTI) with a few minutes tweaking and the repeatability is within 0.008mm probing at 500mm/min.

Probing at 50mm/min the repeatability goes up to 0.005mm (both figures obtained from a loop of 100 probes writing the result into a file and finding the maximum difference) Perhaps it could get even better with some debounce tuning in LinuxCNC but that’s good enough for me.

The only thing that confused me slightly is that the probe is not an isolated switch and has both wires grounded through the tool holder when the probe isn’t activated. This meant a slight change to my wiring to use a pullup resistor.

I’m very happy with this probe and pleased I bought it.

Well done Saulius.

Hi Russel,

I am really pleased you are happy with your new touch probe! Please let me know if you run into some unseen issues. And don’t break it :)

—

BR,

Saulius

Hi Russel, could you help me with the configuration on LinuxCNC please. I have a couple of touch plates on my Router and don’t like invert the Sauliu’s probe signal by the relay solution.

Thanks.

It’s possible to interface your touch probe with heidenhain tnc 370

Hi Paolo, my touch probe has closed circuit in 0 position, and circuit breaks when it moves out of resting spot. I am not familiar with TNC370, so please check if it has similar interface.

—

BR,

Saulius

Hi, I bought a probe from Wildhorse and I am very saddened by the fact that it is virtually useless, poorly assembled at that point that I was impossiblile calibrate it. Desperately seeking an option with good accuracy and that there is no need to calibrate it every time it is mounted on the spindle. I love LinuxCNC and I would preferably use probe normally open, otherwise I’ll appreciate a help to use your probe without the need to add the classic relay, I mean with a more secure solution like Arduino. I have another normally open fixed probe mounted on my Router that I would like keep with its setting. Can you help us setting your touch probe inverting the signal with Arduino in LinuxCNC. I found this site http://rkmiit.ru/main/all/students/educational/tutorials/arduinolinuxcnc.html and suppose you understand russian language.

Thanks so much in advance.

Thank you for notes and link. Been in your shoes :) Was looking for a decent touch probe, and decided to make a better one. For me first time calibration procedure took about about 5 minutes. I know some electronics for signal shaping could be implemented, but I decided to go one step at a time. Also there are ideas on implementing wireless (optical) link.

The following lik shows an example “http://www.cnczone.com/forums/benchtop-machines/180842-touch-plate-nc-touch-probe-switch-inversion.html” on CNCzone on how to implement the probe with Arduino in Mach3, it would be very useful not only a tutorial on your touch probe on Windows but also on Linux, with the advent of Mach4 there are more people that pass to LinuxCNC as a more valid alternative to control the CNC. If you are willing to give it a try I would send you an Arduino for the solution that I asked you.

Thankyou for the promt reply.

No need to send arduino, have bunch of them in my drawer. Could you please tell me why you need to invert signal?

,because I have two touch plates on the router, the first is fixed and measures the length of the tool, I need the second plate to find the workpiece zero in Z axis. Both works only NORMALLY OPEN on my BOB, the ground wire is connected to the body of Router and the router bit closes the circuit when it contacts the touch plate, this solution is very simple and effective. In the past I setted the NORMALLY CLOSED Wildhorse probe inverting the signal by a relay circuit, but I don’t like this solution because I had bounce issues on the mechanical switch.

Hello, you got a very intresting looking product there.

I’ve got a couple of questions:

The probe tip: Where caould i get replacements if it brakes? Is it a standard part?

Is it able to probe both axial and Radial?

Thanks.

/Peter

Hi Peter,

thank you for kind words.

1. Probe is Renishaw compatible with M3 thread (exact part number is A-5003-0057) made by telesmetrology. Slightly cheaper but I have no issues with it’s quality.

2. That’s right probe opens connection on axial and radial contact.

—

BR,

Saulius

Very nice, Thank you for fast answers.

Last questions:

What kind of cable(if any) is attached to the connector?

Do you have a scope diagram of the swiching waveform (im looking for bounce, to be precise).

Best regards,

/Peter

Hi Peter,

Cable has markings [TASKER @ C 123 1×0.25 SPIRAL SHIELDED CABLE LOW CAPACITY MADE IN ITALY]. I provide 2m cable already soldered.

Take a look at few combined pictures at different time scales: http://lukse.lt/failai/LP0018/waveforms.png

—

BR,

Saulius

Nice, Thank you.

I will place the order on ebay right away.

/Peter

Glad to hear! Will ship on Monday.

Please drop me a note when you test it.

—

BR,

Saulius

I jsut opened the package. Everything looks in order

Hi, mate you are feeding my OCD!!! Don’t forget me please.

Hrmm.. press the enter a bit to fast there…

As i Wrote:

Everything looks in order. Comes packaged in (what appears to be, havent measured) ESD protective bubblewrap, Not really nessesery, but a nice touch =)

Fast shipping to Norway. 5 working days since I placed the order. Good work!

Build Quility looks as described and teh probe has a nice “feel” to it.

Supplied cable is acording to spec and the cute ööittöe connector is to die for <3

I havent had a look at the soldering, but will do so after im finnished playing around with it.

So far, it looks and feels just as promised. Thumbs up.

/Peter

Video please, Youtubers are awaiting…

Hi Peter, glad to hear package arrived safe.

Hi Saulius,

I can’t pay the probe on eBay. The transaction is blocked, can you help me please?

Hi,

this is probably because none is left on eBay. Please check an error.

—

BR,

Saulius

Good for you mate! Are you planning make some more in the next days. Please if yes notify me, I’m interested in buying and setting your probe with Arduino. Thanks

I should have some more next week. Will reserve one for you.

Nice, Grazie tante!

Hi, it took a little bit longer. If you still need one, I sent you details to email. Please check.

Hi, I got my probe.

can you provided instruction how to assemble to my cnc router.

thanks

Marc

Hi Marc, would you please be so kind letting me know what router/setup do you have?

—

BR,

Saulius

Hi Saulius,

This mornig I received the probe and order the following part to invert the signal: http://www.cabur.it/productsheet.asp?p=10359&descr=Invertitore%20di%20segnale%20serie%20CI&l=2

Thank you again.

Hi, glad you received it and interesting finding. Please let me know how it performs and how much does this inverter cost?

—

BR,

Saulius

Hi Saulius here is the link to the post where I explain how to connect your “NC” probe to LinuxCNC without any external hardware and mantain the “NO” touch plate plugged into the same pin port (NO)that the stylus probe is, https://forum.linuxcnc.org/forum/22-pyvcp/28572-monster-a-learning-experience-pyvcp-machine?start=30#63572 .I Hope it’s going to be useful to the LinuxCNC users.

Unfortunately I crashed my probe and ruined the Stylus, could you please sell me one or two spare stylus?

Thank you

Hi, sorry to hear you broke stylus. And thank you for a link. Opened new e-shop recently http://www.kurokesu.com/ and also will be sharing various useful information. As for stylus – please check your email for more details.

—

BR,

Saulius

Hi Saulius,

I am interested to buy a probe from you, are they still available for purchase?

As I understood these will work fine using MACH3?

Thanks,

Ard

Hi Ard, I am setting new batch which will have much better surface plating instead of black oxide. New samples should be available in a few weeks. And yes – this touch probe is fully compatible with Mach3.

—

BR,

Saulius

OK, could you send me an email when you have them again?

Thank you!

Ard

Hi Ard, no problem. Will inform you when it will be available.

How do you wire it to the control unit. I have a x6-2200 china router by omiocnc

Hi John,

Connecting touch probe to machine running Mach3 or LinuxCNC is pretty straight forward. You define pin which is responsible for this function and connect it to your controller. While I can help configuring Mach3 I can’t tell where exactly you should connect to x6-2200 machine.

—

BR,

Saulius

Hi Saulius,

I may be interested in using your touch probe on some of our machines in the near future. Currently we are using Tormach passive probes, which are not sealed as yours are. The probes see pretty heavy use, and have to be cleaned every month or so.

Assuming the connection points on your probe would have to be serviced at some point, what is involved in accessing the points and replacing the fluid?

Thanks,

David

Hi David,

Thank you for your interest. This probe was designed to minimize need of service. It is pretty easy to take it apart and put back. Unscrew bottom cap and you have access to all parts. I use deoxit fluid over gold plated contacts, combined with sealed case under normal usage it should take long time until service is required.

All information and sales moved to http://www.kurokesu.com. Feel free to visit.

—

BR,

Saulius

Hello, as I saw on ebay descrption, it is 5-way probe. Is that correct? I assumed that using 3 pairs of ball it is 3-way?

Thanks

Hi Valery,

This probe 5-way. You are correct it is based on classic design rods seated on 6 balls.

—

BR,

Saulius

I’m having an ER11 collet chuck and the 8 mm shank would force me to use an oversized collet so I would prefer a smaller size.

Will there be a smaller sized shank available in the near future?

Is the shank just screwed for easy replacement?

BR

Thomas

Hi Thomas, I can reduce shank to 7mm. For more details please check email.

Can this be used with Tormach PCNC1100 and PathPilot controller?

Sure, it will work perfectly with PCNC1100 and PathPilot.

—

BR,

Saulius

With the PCNC1100, will the supplied electrical cable connect to the probe port on the Tormach out of the box? Or is some cable adapter required?

Hi again Saulius!

I have been working with your probe for a nice while now and its really good!

During a re-wiring of my machine i accidently pulled GND and +24 in to the probe…which melted the plastic part that holds the 6 small springs..or rather heated the springs so much that they damaged the white cup they reside in :( TOTALLY MY BAD.

So now i’m wondering if you would sell me a new plastic part (the one with the springs) and 6 springs along with it.

Best regards Peter

Hi Peter,

Sorry to hear you damaged plastic part. While working on new wireless design and switching to another manufacturer have only defected parts left. Maybe you can you recondition spring holes (2.0mm)? I can send you new springs and defected plastic part. Will write you email soon with more details.

—

BR,

Saulius

Wow your second round probe looks and design are absolutely superb from what I gather on your blog. Then I see the above comment of a wireless one in the works – can’t wait- if you need a paying tester of the wireless version please ping me as I have been searching for a wireless one with good precision and repeatability to leave in the ATC on the PCNC1100 series 3 with path pilot. Hope to hear from you soon.

Thanks

Iwan

Hi Iwan, appreciate your interest. Will inform you by email when there will be anything to test.

—

BR,

Saulius

Good morning. Do you have numbers for the activation force of the probe? I’m primarily interested in Z activation force, but X and Y (and I guess then 120°, 240° and 0/360° – in line with the internal pivots) would also be valuable.

Thank you for any information you can provide,

Josh

Hi Josh, I will check tomorrow and let you know.

Talk about response time X)

Thank you Saulius – I look forward to that.

Axial activation load ~10N, Radial ~2N.

Hello. This looks like a beautifully made probe. Are you planning to manufacture another batch of wired (non-wireless) probes? If you are, do you know when these might be available for sale?

Thanks for your time.

Hello John. Actually I do. Waiting for last pieces to arrive in a week or two. I will let you know more details as soon as new touch probe will be functional.

Hi Saulius, mate don’t forget me please! WiFi x1.

Cheers,

Floris

Floris, added to notification list too.

I would like to let you know that new CNC touch probe TPA2 is assembled now and being tested for any flaws. First units will be assembled and put on stock soon. Meanwhile feel free to read short introduction: http://www.kurokesu.com/main/2016/10/25/announcing-tpa2-touch-probe/

Hello, Saulius, are the 2nd edition available for sale?

Thanks

Valery

Hi Valery. Yes, TPA2 is available on kurokesu e-shop. You can read more about it here: http://kurokesu.com/main/2016/10/30/first-batch-of-touch-probe-tpa2-is-now-available/

Hi,

Just stumbled across your TPA2 and it looks like exactly what I want… I see the product page says pre-order only, but I am unable to actually do a pre-order as I can’t add to cart.

Any way to sign up for notification or pre-order with you?

Cheers

Hi Adrian, thank you for contacting. My CNC house is late to deliver parts – probes should be available first week of February. Will notify you personally as soon as I have them on stock again.

Hello Saulius,

Could you send e-mail notification when the 2nd edition will be available for sale?

Regards,

A.

Hello Andrew, sample batch of TPA2 disappeared instantly :) Now I am preparing for larger order. I think it will take bit longer than a month.

p. Sauliau,

mes prekiaujame metalo apdirbimo įrankiais CNC staklėms.

Labai įdomus prietaisas.

Musų klientai klausinėja apie tokius.

Ar galima butų jį apžiūrėti ir pasiūlyti musų klientams?

Pagarbiai,

Gintaras Urbanas

Gintarai, žinoma galima. Parašiau laišką, galėsim pasitarti.

Dear Sir, my name is Renato Oliveira from Brazil, could you send me price and delivery time, please?

Hi Renato, please check Kurokesu e-store https://www.kurokesu.com/shop/precision_instruments/TPA2